A sustainable extension transforms BakerBrown’s converted forge

BakerBrown Architects crafts a sustainable extension for a converted forge project in southern England

Ivan Jones - Photography

BakerBrown Architects has an award-winning reputation for sustainable architecture, pioneering ways of reducing a building’s footprint through meticulous design, careful use of resources, and thoroughly practical and attainable methods like insulation and the use of local materials and trades. In a similar vein, its latest work is a sustainable extension that makes the most of a unique site that brings together past, present and future.

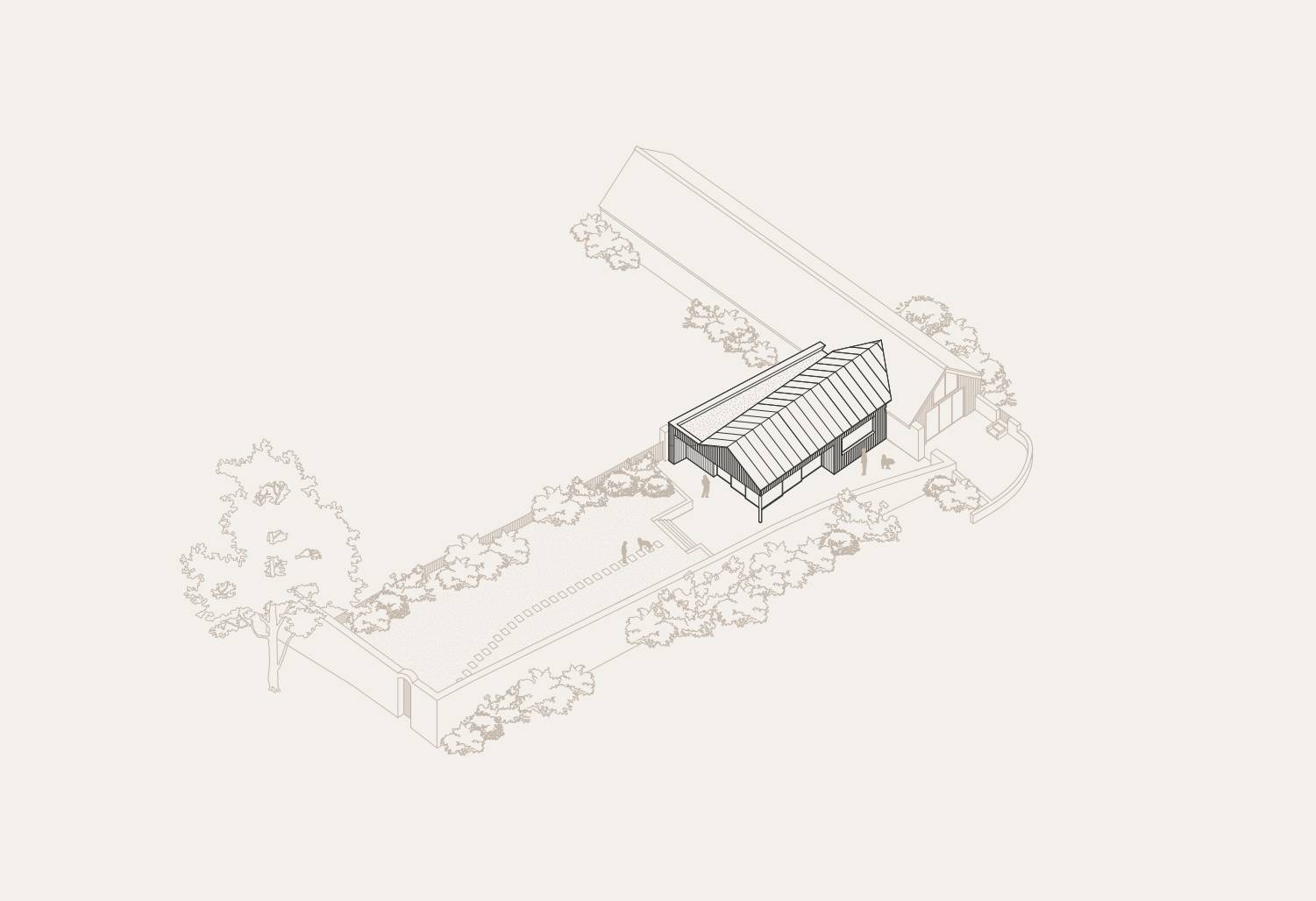

The practice’s most recent project is a conversion of a long, low, gabled dwelling house in the south of England.

The original structure was once the village forge, making all manner of metal goods for local farmers and businesses. It was subsequently converted into a house and the surrounding neighbourhood upgraded to a Conservation Area.

The clients approached BakerBrown with the intention of creating a better relationship between the house and its garden, set at 90 degrees to the original structure.

The architects also had to upgrade the original masonry building. Built in the era between insulation and proper damp-proofing, it was becoming uneconomical to run.

The primary change is the creation of an extension that reaches out into the walled garden, transforming what was a modest sunroom into a large open-plan kitchen and dining room. A new red zinc pitched roof oversails the extension, providing solar shading for the glazing.

The main building has been overclad to radically improve its ability to retain heat in the winter and cool air in the summer.

Wallpaper* Newsletter

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Outside, a new rainscreen has been made from locally sourced sweet chestnut, adding to the increased thermal performance of the building.

The original boiler was replaced with a heat pump; despite increasing the floor area by around 40 per cent, the combination of more efficient heat generation and better insulation has reduced the property’s energy consumption.

All the design details are carefully considered with energy-saving in mind. The polished concrete floor slab in the extension acts as a heat sink, drawing in warmth from the glazing in winter. Sustainable birch plywood is used for the kitchen, ceilings, and joinery, lightly oiled to reflect light, while traditional vernacular elements like the original flint wall are retained and exposed.

Set up by Duncan Baker-Brown in 1994, the studio is based in East Sussex, and frequently works with vernacular forms, existing buildings, and conversions. Past projects include The Waste House – made, as the name suggests, from waste materials; and The House That Kevin Built, prefabricated using 90 per cent bio-based materials and the UK’s first EPC A* rated home. In 2017, BakerBrown authored The Re-Use Atlas: A designer’s guide to the circular economy, a pioneering book looking at how architects can make better use of limited resources.

INFORMATION

Jonathan Bell has written for Wallpaper* magazine since 1999, covering everything from architecture and transport design to books, tech and graphic design. He is now the magazine’s Transport and Technology Editor. Jonathan has written and edited 15 books, including Concept Car Design, 21st Century House, and The New Modern House. He is also the host of Wallpaper’s first podcast.

-

All-In is the Paris-based label making full-force fashion for main character dressing

All-In is the Paris-based label making full-force fashion for main character dressingPart of our monthly Uprising series, Wallpaper* meets Benjamin Barron and Bror August Vestbø of All-In, the LVMH Prize-nominated label which bases its collections on a riotous cast of characters – real and imagined

By Orla Brennan

-

Maserati joins forces with Giorgetti for a turbo-charged relationship

Maserati joins forces with Giorgetti for a turbo-charged relationshipAnnouncing their marriage during Milan Design Week, the brands unveiled a collection, a car and a long term commitment

By Hugo Macdonald

-

Through an innovative new training program, Poltrona Frau aims to safeguard Italian craft

Through an innovative new training program, Poltrona Frau aims to safeguard Italian craftThe heritage furniture manufacturer is training a new generation of leather artisans

By Cristina Kiran Piotti

-

A new London house delights in robust brutalist detailing and diffused light

A new London house delights in robust brutalist detailing and diffused lightLondon's House in a Walled Garden by Henley Halebrown was designed to dovetail in its historic context

By Jonathan Bell

-

A Sussex beach house boldly reimagines its seaside typology

A Sussex beach house boldly reimagines its seaside typologyA bold and uncompromising Sussex beach house reconfigures the vernacular to maximise coastal views but maintain privacy

By Jonathan Bell

-

This 19th-century Hampstead house has a raw concrete staircase at its heart

This 19th-century Hampstead house has a raw concrete staircase at its heartThis Hampstead house, designed by Pinzauer and titled Maresfield Gardens, is a London home blending new design and traditional details

By Tianna Williams

-

An octogenarian’s north London home is bold with utilitarian authenticity

An octogenarian’s north London home is bold with utilitarian authenticityWoodbury residence is a north London home by Of Architecture, inspired by 20th-century design and rooted in functionality

By Tianna Williams

-

What is DeafSpace and how can it enhance architecture for everyone?

What is DeafSpace and how can it enhance architecture for everyone?DeafSpace learnings can help create profoundly sense-centric architecture; why shouldn't groundbreaking designs also be inclusive?

By Teshome Douglas-Campbell

-

The dream of the flat-pack home continues with this elegant modular cabin design from Koto

The dream of the flat-pack home continues with this elegant modular cabin design from KotoThe Niwa modular cabin series by UK-based Koto architects offers a range of elegant retreats, designed for easy installation and a variety of uses

By Jonathan Bell

-

Are Derwent London's new lounges the future of workspace?

Are Derwent London's new lounges the future of workspace?Property developer Derwent London’s new lounges – created for tenants of its offices – work harder to promote community and connection for their users

By Emily Wright

-

Showing off its gargoyles and curves, The Gradel Quadrangles opens in Oxford

Showing off its gargoyles and curves, The Gradel Quadrangles opens in OxfordThe Gradel Quadrangles, designed by David Kohn Architects, brings a touch of playfulness to Oxford through a modern interpretation of historical architecture

By Shawn Adams