Jun Kamei’s fabric innovations are breathing life into a sustainable future

Innovative material technology developed by Jun Kamei for an underwater future has spawned a new sportswear fabric that can be endlessly reused and recycled

In partnership with E.ON

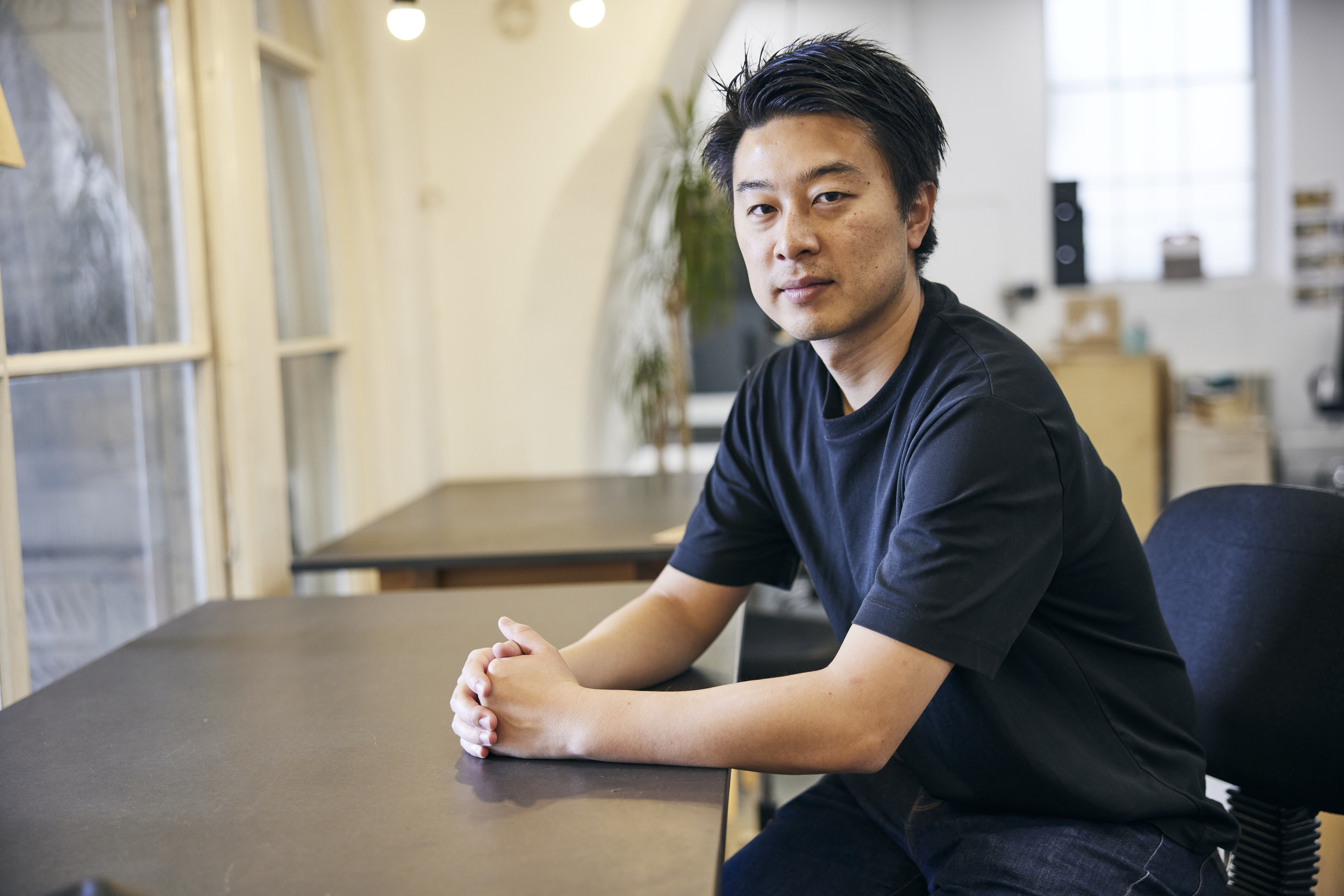

Finding a way to thrive in the Earth’s ever-evolving environment and rapidly changing climate requires radical thought, innovative application and sustainable solutions. Where others might see disaster and dystopia, the truly transformative mind – that of biomimicry designer Jun Kamei, for example – manifests opportunity, challenge and adventure.

With the world’s temperature predicted to increase 3.2℃ by the year 2100 (according to a report by The Intergovernmental Panel on Climate Change), causing a sea level rise that would affect billions of people and submerge some coastal cities altogether, Kamei is thinking not of flood but an amphibious future: ‘A time where large percentages of the planet’s population will spend as much time in the water as on the land,’ he says.

Jun Kamei’s amphibious garment for an underwater future

Jun Kamei and team working with their specially developed fabric

With the help of Kamei’s revolutionary gill garment – a vest and accompanying mask intended to facilitate underwater breathing for humans – a recreational dive to a neighbouring church, a night swim through submerged streets or even a sub-aqua commute from home to work may be possible.

Developed by London’s Royal College of Art, in collaboration with the RCA-IIS Tokyo Design Lab, Amphibio is a 3D-printed, amphibious garment made from a specially developed material that supports underwater breathing by replenishing oxygen from the surrounding water and dissipating the carbon dioxide that accumulates in the system.

‘The technology for Amphibio was inspired by diving insects surviving underwater by virtue of a thin layer of air trapped on their superhydrophobic skin surface, which works as a gas exchanging gill,’ explains the designer. ‘Using 3D-printing technology, our newly developed material can be shaped in complex forms to do the same thing.’

Fabric testing

It’s a big idea to help solve a major problem but Kamei is not fazed by the ambitious enormity of the task ahead. ‘I feel that designers should not be scared of tackling the bigger problems,’ he says. While the design community tends to operate at ‘product level’, his kind of micro design thinking can actually prove pivotal in tackling the macro and complex issues around climate change and seismic environmental shifts.

The yarn used for the prototypes

‘I would urge people wanting to take action on climate change challenges to be informed of the actual science,’ says Kamei. ‘Any ideas must always consider the science first.’

With his invention still in the prototype stage, Kamei’s next action is testing Amphibio to support underwater breathing. ‘If you are familiar with free-diving and scuba-diving equipment, Amphibio sits right in between those two,’ he says. ‘Our membrane technology enables the material itself to collect oxygen dissolved into seawater. In the near future, the wearer would stay underwater for longer, but with far less equipment (such as heavy oxygen tanks) than you need for conventional scuba diving.’

Adapting the concept for sustainable sportswear

Prototype sustainable sportswear made using Amphitex, a 100 per cent recyclable alternative to traditional waterproof breathable textiles

This kind of future-facing research and design has produced some exciting applications for the wider present – the discovery that Amphibio’s membrane technology is also suited for the manufacture of waterproof, breathable sportswear textiles for everyday use on dry land.

‘The principle is really simple,’ says Kamei, ‘a combination of material science, and modern technology. Our Amphitex material is waterproof, but the membrane’s micro pores allow gases to pass through it. Which means that oxygen is able to travel from the water to the inside without actually letting any water pass.’ And unlike many of its sporting and impermeable competitors currently on the market, Amphitex – which is free from PTFE (polytetrafluoroethylene) and is made from a single-source (or mono) material, making it 100 per cent recyclable – is truly sustainable.

Both projects, Kamei says, are hard-wired to a sustainable future, ‘in the sense that everything we do is to mitigate the impact of climate change. It's definitely important to have a multidisciplinary eye when you tackle sustainability challenges. By trying something radically conceptual, future-oriented and different, we ended up creating Amphitex. You start with one idea and then another door opens and that leads to another door. In material science, things have a tendency to morph like this – you invent something and then you realise that it might have an application in places that you’ve never thought about before.’

Being chosen as a Change Maker is an honour, says Kamei, ‘but it also comes with responsibility. It’s now very important for me to deliver on what I promised to do and bring positive results for the environment.’

Meet more Change Makers – people who are taking action for climate – at eonenergy.com

Wallpaper* Newsletter

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

-

Put these emerging artists on your radar

Put these emerging artists on your radarThis crop of six new talents is poised to shake up the art world. Get to know them now

By Tianna Williams

-

Dining at Pyrá feels like a Mediterranean kiss on both cheeks

Dining at Pyrá feels like a Mediterranean kiss on both cheeksDesigned by House of Dré, this Lonsdale Road addition dishes up an enticing fusion of Greek and Spanish cooking

By Sofia de la Cruz

-

Creased, crumpled: S/S 2025 menswear is about clothes that have ‘lived a life’

Creased, crumpled: S/S 2025 menswear is about clothes that have ‘lived a life’The S/S 2025 menswear collections see designers embrace the creased and the crumpled, conjuring a mood of laidback languor that ran through the season – captured here by photographer Steve Harnacke and stylist Nicola Neri for Wallpaper*

By Jack Moss