Mr Big Stuff: designer Joris Laarman takes 3D printing large

In 2003, Joris Laarman – who had only just graduated from Design Academy Eindhoven – redefined one of the most mundane and overlooked household objects: the radiator. His curvaceous design considered how heat is transmitted, but came with plenty of rococo-inspired spin. When Wallpaper* magazine celebrated its first ten years in 2006, the ‘Heatwave’ radiator was included in our selection of the decade’s most influential designs. Eleven years on, the piece that skyrocketed Laarman to design stardom remains one of the most memorableconcepts in the field.

‘It was a complete rethink of the radiator, from appearance to efficiency,’ says Caroline Baumann, director of New York’s Cooper Hewitt design museum, which acquired a model in its permanent collection in 2008. ‘It showed that ornament can be inherently functional, and challenged the dogma of functionalism with Baroque exuberance.’

This month, an exhibition chronicling Laarman’s work to date will open at the Cooper Hewitt, before moving on to the High Museum in Atlanta and Houston’s Museum of Fine Arts.

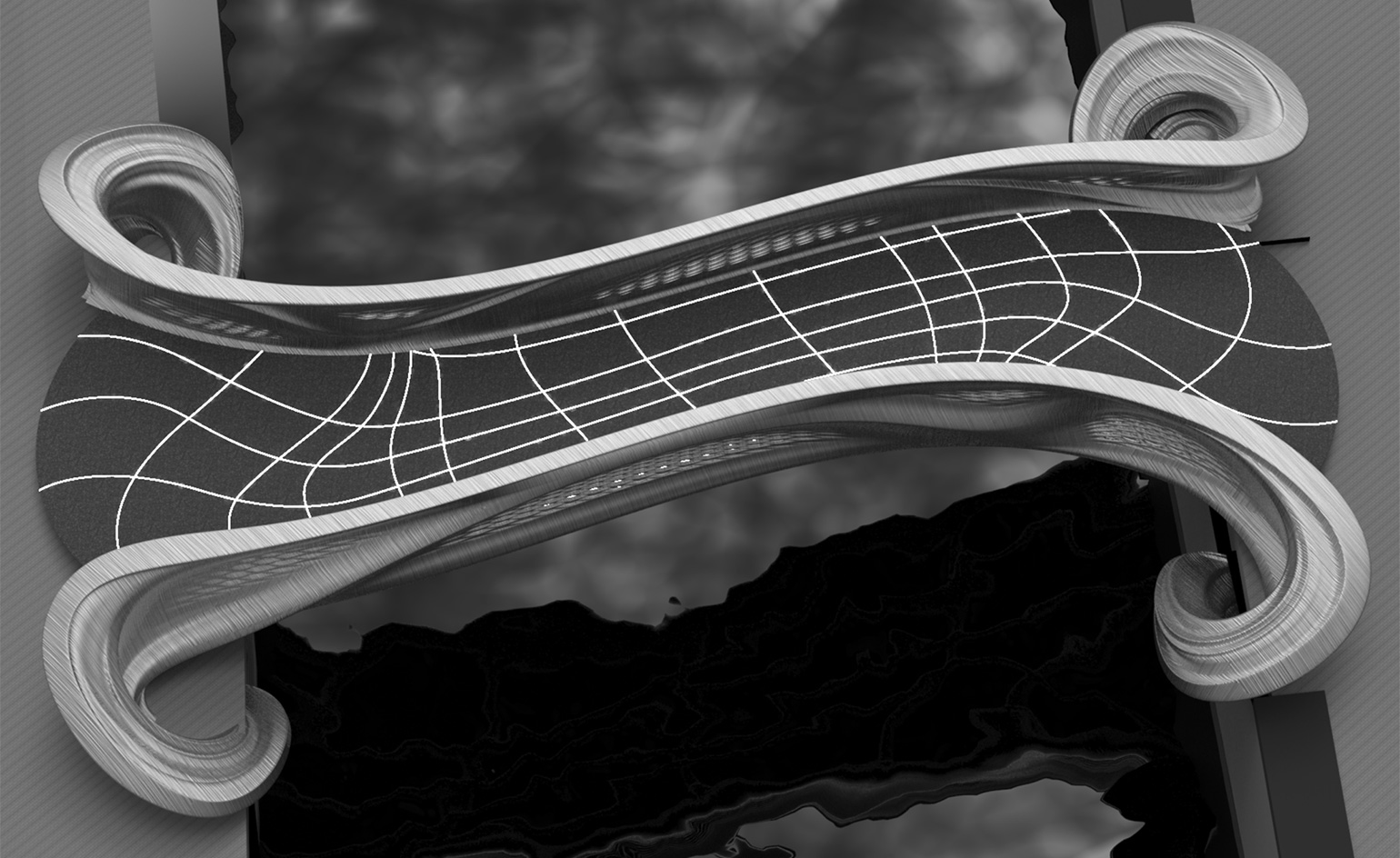

A rendering of the bridge, a scale model of which will be on display at the Cooper Hewitt.

The works on show offer a glimpse of Laarman’s reach as a designer and a maker, but also as a thinker and an explorer of imagined futures. ‘I have a broad interest in the world,’ he says. ‘I am very much the author of a certain story about progress.’ His interests include futurism and modernism, economics, technological progress, predictions from science fiction movies of the past, as well as changes in global temperatures and stock markets, which give him an idea of the pace of the world’s development. ‘I kind of surf the waves of innovation and try to give them a face or form. The things I make are frozen moments in this timeline.’ This process makes for a body of work with a wide range of visual codes, usually originating from manufacturing experiments.

Laarman launched his studio in 2004 with his partner, filmmaker Anita Star, dubbing it a ‘lab’: ‘It’s a lab in the sense that we are not an industrial design brand, we experiment like scientists to make stuff,’ he explains. ‘The Lab is a hive of R&D activity that brings together engineers, craftspeople, designers and programmers to develop new skills, materials and digital technologies,’ adds Baumann. ‘It’s transforming our understanding of materiality, pushing the boundaries of form, and even surpassing the limitations of industrial production.'

Some of the lab’s creations, such as the ‘Bone’ chair, have become design icons. Launched in 2005, it marked the beginning of Laarman’s love affair with digital fabrication. The aluminium chair (and its accompanying series, including a rocker – see our Sotheby’s auction story) was produced using technology that mimics the growth of a tree, or of bones in the human body. It is designed through an algorithm to use minimal material, with a shape very much guided by the technology, leaving an element of surprise to the design process. Another project that exemplifies the breadth of Laarman’s experimentation, and that will be included in the travelling show, is the Maker series of furniture. A symbiosis between craftsmanship and technology, the range started with a chair, composed of digitally fabricated wooden modular parts. The project is based on the idea that anyone could produce the furniture using a domestic 3D-printing machine, or small consumer CNC-milling tools (the code for the chair was published under a Creative Commons licence so that it could be downloaded by anybody).

A rendering showing a top view of the curved, asymmetric design.

‘Joris’ work has never ceased to develop,’ reflects his New York gallerist Marc Benda, who has worked closely with Laarman since 2005. ‘He has helped substantially in bringing the practice of contemporary design, especially studio work, into the 21st century.’ One key development, Benda notes, has been in the way Laarman has harnessed the latest technology, graduating from revolutionary domestic design projects to collaborating with material and building specialists on a massive scale.

In 2014, Laarman and Star set up a new company, MX3D (standing for Multi Axes 3D printing), with the intention of taking digital fabrication to an industrial scale. ‘Right after our first experiment with robots and 3D printing,’ says Laarman, referring to the sculptural ‘Dragon’ bench created that year using a metal 3D printer and a combined robot/welding machine, ‘we were thinking about how we could scale this up. The technology was too good to be true, and too good to just keep as a tool to make the designs that I came up with. So we partnered with people who create the software, who provide the materials, the welding machines and the robots to establish MX3D.’

Laarman is working on his largest MX3D project yet, the first (and probably last, he jokes) piece of infrastructure he has created. With his team, he is printing a bridge for the city of Amsterdam, to be completed in summer 2018. ‘We needed a poster project for the company, so we thought of doing something for Amsterdam, and what could be better than a bridge, since we are in a city full of bridges and water?’ In a ‘smart’ approach to building, the construction hinges on just one machine, which prints in a cost-effective manner, while the design, engineering and manufacturing processes are interwoven. When complete, the structure may be fitted with sensors able to collect data ‘about the bridge or about the traffic’, adds Laarman. The upcoming US exhibitions will showcase a 3D-printed scale model of the bridge, and a new piece, the ‘Gradient’ screen, created using the same algorithm. The shows will be accompanied by a new edition of the book, Joris Laarman Lab (August Editions), edited by Star, who has also created video content for the exhibitions, offering a behind-the-scenes peek into life at the lab.

The exhibited works only offer a glimpse of Laarman’s potential, ‘a sliver of the universe that he is in the process of building’, says Benda. ‘The future of any creative practice rests on what comes next, and in Laarman’s case, there is a noticeable lack of time in his life: there is simply not enough time in a lifetime to do all the things he is setting out to do. That is a hallmark of a great mind and a great practice.’

As originally featured in the October 2017 issue of Wallpaper* (W*223)

A section of the MX3D bridge. Once completed, the 3D-printed metal parts will be welded together on site by robot arms.

Laaran’s designs combine technology with ornamentation. Pictured, ‘Heatwave’ radiator, 2003

The exhibition at Cooper Hewitt, pictured, features Laarman's most iconic designs, including his Heatwave radiator from 2006. © Smithsonian Institution

‘Branch’ bookshelf, 2010

Laarman’s ‘Digital Matter’ project, part of the exhibition at Cooper Hewitt, a project he has developed since 2010 exploring the endless possibilities of digital manufacturing. © Smithsonian Institution

‘Maker Chair (Polygon)’, 2014

A series of Laarman’s ‘Makerchairs’, photographed at Cooper Hewitt and including the designs’ abstract patterns featuring on the wall. © Smithsonian Institution

‘Dragon’ bench, 2014

INFORMATION

‘Joris Laarman Lab: Design in the Digital Age’ runs from 27 September 2017 to 15 January 2018. For more information, visit the Cooper Hewitt website, and the Joris Laarman website

ADDRESS

Cooper Hewitt

2 E 91st Street

New York NY 10128

Wallpaper* Newsletter

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Rosa Bertoli was born in Udine, Italy, and now lives in London. Since 2014, she has been the Design Editor of Wallpaper*, where she oversees design content for the print and online editions, as well as special editorial projects. Through her role at Wallpaper*, she has written extensively about all areas of design. Rosa has been speaker and moderator for various design talks and conferences including London Craft Week, Maison & Objet, The Italian Cultural Institute (London), Clippings, Zaha Hadid Design, Kartell and Frieze Art Fair. Rosa has been on judging panels for the Chart Architecture Award, the Dutch Design Awards and the DesignGuild Marks. She has written for numerous English and Italian language publications, and worked as a content and communication consultant for fashion and design brands.

-

Japan in Milan! See the highlights of Japanese design at Milan Design Week 2025

Japan in Milan! See the highlights of Japanese design at Milan Design Week 2025At Milan Design Week 2025 Japanese craftsmanship was a front runner with an array of projects in the spotlight. Here are some of our highlights

By Danielle Demetriou

-

Tour the best contemporary tea houses around the world

Tour the best contemporary tea houses around the worldCelebrate the world’s most unique tea houses, from Melbourne to Stockholm, with a new book by Wallpaper’s Léa Teuscher

By Léa Teuscher

-

‘Humour is foundational’: artist Ella Kruglyanskaya on painting as a ‘highly questionable’ pursuit

‘Humour is foundational’: artist Ella Kruglyanskaya on painting as a ‘highly questionable’ pursuitElla Kruglyanskaya’s exhibition, ‘Shadows’ at Thomas Dane Gallery, is the first in a series of three this year, with openings in Basel and New York to follow

By Hannah Silver

-

Basic.Space launches its first IRL shopping event – in an empty West Hollywood mall

Basic.Space launches its first IRL shopping event – in an empty West Hollywood mallWith the launch of its first in-person event in LA this weekend, the e-commerce platform is looking to bring collectible design to a whole new audience

By Adrian Madlener

-

Design Miami 2024 is alive with possibility: here are 14 things to see

Design Miami 2024 is alive with possibility: here are 14 things to seeDesign Miami 2024 opens 4-8 December – let Wallpaper* guide you to the highlights, from dazzling installations to plump sofas and anthropomorphic sculptures

By Ali Morris

-

Nendo’s collaborations with Kyoto artisans go on view in New York

Nendo’s collaborations with Kyoto artisans go on view in New York‘Nendo sees Kyoto’ is on view at Friedman Benda (until 15 October 2022), showcasing the design studio's collaboration with six artisans specialised in ancient Japanese crafts

By Pei-Ru Keh

-

Italian craftsmanship comes to Los Angeles in this eclectic Venice Canals apartment

Italian craftsmanship comes to Los Angeles in this eclectic Venice Canals apartmentBoffi Los Angeles celebrates a juxtaposition of texture throughout a waterside bolthole

By Hannah Silver

-

Design Miami/Basel 2022 explores the Golden Age

Design Miami/Basel 2022 explores the Golden AgeDesign Miami/Basel 2022, led by curatorial director Maria Cristina Didero, offers a positive spin after the unprecedented times of the pandemic, and looks at the history and spirit of design

By Rosa Bertoli

-

Kvadrat’s flagship New York showrooms encompass colourful design codes

Kvadrat’s flagship New York showrooms encompass colourful design codesIndustrial designer Jonathan Olivares and architect Vincent Van Duysen have worked with Danish textile brand Kvadrat on the vast new space, also featuring furniture by Moroso

By Hannah Silver

-

What to see at New York Design Week 2022

What to see at New York Design Week 2022Discover Wallpaper’s highlights from New York Design Week 2022 (10 – 20 May 2022): the fairs, exhibitions and design openings to discover

By Pei-Ru Keh

-

Colour defines LA ceramics studio and showroom of Bari Ziperstein

Colour defines LA ceramics studio and showroom of Bari ZipersteinStep inside the multifunctional ceramics studio, office and showroom of designer and artist Bari Ziperstein, designed by local firm Foss Hildreth

By Pei-Ru Keh