Gold standard: creating Fabergé’s modern treasures

Of all the decorative crafts, enamelling is, and always has been, one of the toughest to master. Which is exactly why Carl Fabergé was so attracted to it. The outmoded enamelled guilloché techniques of 18th century French craftsmen Fabergé had come upon in museums during his European Grand Tour of the 1860s inspired the master goldsmith to revive them.

He also saw the potential for producing a spectrum of rich, glossy colours and tasked his workshops with developing a Fabergé palette. One hundred and forty-five shades were created, including the sugared-almond-like lilacs, pinks and yellows that denote the Fabergé style. The house further amazed its peers in its mastery of ‘in the round’ or – en ronde bosse – enamelling, which was crucial to its egg designs. The curves made it torturously difficult to achieve consistency in the liquified glass during firing in impossibly hot kilns.

Fabergé employs British-based jewellers and enamel artists to create traditional guilloché patterns in gold

Today, without the patronage of the kings and tsars that Carl Fabergé served, and with many traditional techniques now obsolete, it is not possible for a craftsman to spend a year embellishing one object, such as a Fabergé egg, to the impossibly exquisite level achieved by his 19th century St Petersburg workshops, and which continues to make original Fabergé pieces so awe-inspiring. But guilloché enamelling is still a mainstay of Fabergé, with elements appearing in the house’s contemporary jewellery, egg and watch designs.

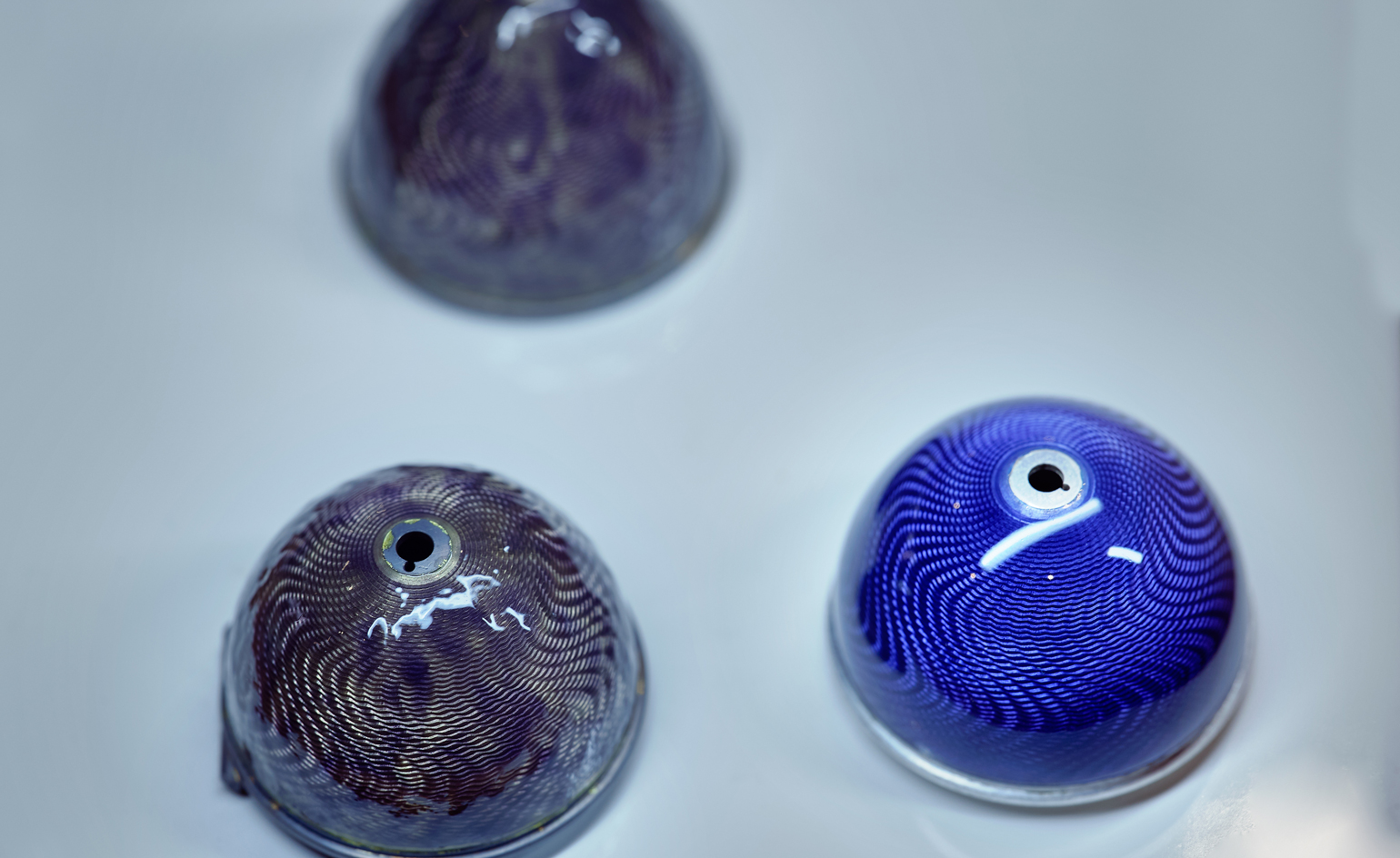

Now, Fabergé employs British-based jewellers and enamel artists to create traditional guilloché patterns in gold. Egg pendants are hand-engraved, so that the enamel – powdered glass in tones reminiscent of the original Fabergé palette – can be applied. When a design is placed in a high-temperature kiln, the enamel fuses with the metal beneath. These layers of opaque colour highlight the swirled patterns of the gold, creating the illusion of shimmering, opalescent waves of light.

Guilloché metal patterns were typically created using a lathe. Fabergé craftsmen engrave them in gold by hand

Three egg parts in various stages of polish. The piece to the right is complete. After a lengthy firing and polishing process, its desired rich, glossy colour has been achieved

An almost complete Fabergé egg at the British enameller workshop

INFORMATION

ADDRESS

faberge.com

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Caragh McKay is a contributing editor at Wallpaper* and was watches & jewellery director at the magazine between 2011 and 2019. Caragh’s current remit is cross-cultural and her recent stories include the curious tale of how Muhammad Ali met his poetic match in Robert Burns and how a Martin Scorsese Martin film revived a forgotten Osage art.

-

The new Tudor Ranger watches master perfectly executed simplicity

The new Tudor Ranger watches master perfectly executed simplicityThe Tudor Ranger watches look back to the 1960s for a clean and legible design

-

This late-night hangout brings back 1970s glam to LA’s Sunset Boulevard

This late-night hangout brings back 1970s glam to LA’s Sunset BoulevardGalerie On Sunset is primed for strong drinks, shared plates, live music, and long nights

-

How Memphis developed from an informal gathering of restless creatives into one of design's most influential movements

How Memphis developed from an informal gathering of restless creatives into one of design's most influential movementsEverything you want to know about Memphis Design, from its history to its leading figures to the pieces to know (and buy)

-

Art takes London: Tiffany & Co, Damien Hirst and artists take over Selfridges' windows

Art takes London: Tiffany & Co, Damien Hirst and artists take over Selfridges' windowsFour British contemporary artists celebrate Tiffany & Co's pioneering history with a series of storied window displays

-

All smiles: How a grillz jewellery making class in London became an international hit

All smiles: How a grillz jewellery making class in London became an international hitWhat started as a passion project quickly exploded in popularity. We get the story behind the grillz-making workshop at Cockpit London

-

Emerging jewellery designers to get to know

Emerging jewellery designers to get to knowThese independent, new and emerging jewellery designers and brands from New York to Paris are firmly on our radar

-

Playing it cool: pearls are having a moment

Playing it cool: pearls are having a momentWe've been deep-diving into boutiques around the world to find the very best calcium carbonate in minute crystalline form. It seems jewellers have been busy rethinking pearls, with contemporary (and often affordable) results

-

Eternity rings for the modern couple

Eternity rings for the modern coupleEternity rings, whether sleekly minimalist or sprinkled in diamonds, can be a chic and contemporary love token

-

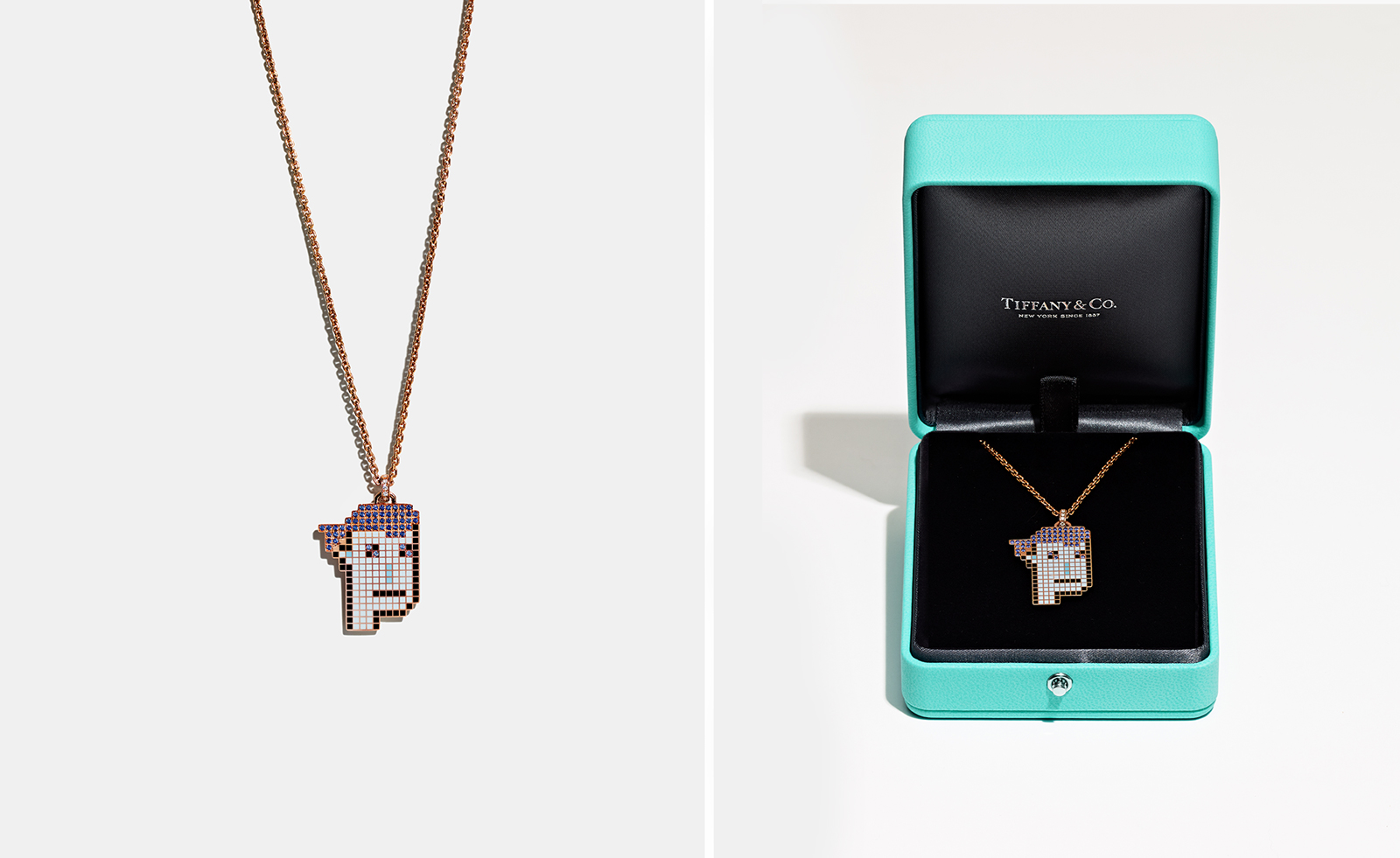

CryptoPunks come to life on Tiffany & Co pendants

CryptoPunks come to life on Tiffany & Co pendantsTiffany & Co has partnered with blockchain infrastructure company Chain to create custom pendants and NFTiffs

-

Order of the day: Pomellato’s high jewellery takes us from dawn to dusk

Order of the day: Pomellato’s high jewellery takes us from dawn to duskPomellato’s new high jewellery collection, La Gioia, tells the story of a day in precious stones

-

Anklets welded onto the body make romantic and enduring jewellery tokens

Anklets welded onto the body make romantic and enduring jewellery tokensAtelier VM’s ‘L’Essenziale’ jewellery collection now includes slender gold anklets